- amtec

- AMTEC English

- Bolted Flanged Joints

- Philosophy

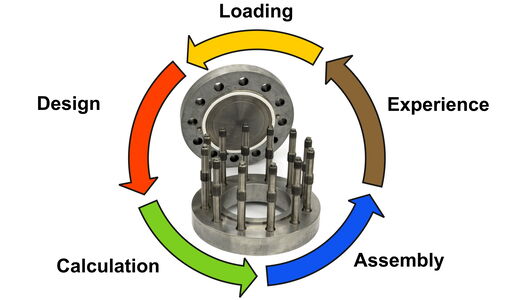

5 steps to a leak-free bolted flange joint

In order to guarantee a correct function - i.e. integrity and tightness - of a flange connection,

- all loads must be known,

- both the construction and the sealing element have to be suitable,

- the required sealing characteristics are available,

- integrity and tightness analysis using above data must be performed and

- the assembly process has to meet the requirements.

The procedure is completed by a consequent

- inclusion of feedback and experience.

Following this procedure, optimizations can be included at any time, if necessary.

In our experience, this is the way to meet the highest demands on tightness and integrity!

Loading

First of all, we determine the real or expected loads, such as temperature, internal pressure or connection loads, and their behaviour with time. If necessary, we measure the actual loading history at the components.

Design

Flanges, bolts and gasket are selected to suit the loads and the medium (geometry and material).

Our gasket characteristics databases assist a reliable gasket selection and they provide gasket factors needed for calculation. If necessary, we determine gasket factors in our test lab.

Calculation

Calculation of flanged connections includes both integrity proof and tightness analysis. For this purpose, there are modules of our software TEMESfl.cal that comply with ASME BPVC Sect. VIII procedures, ASME PCC-1 App. O, EN 1591-1, KTA 3211.2 (German Nuclear Safety Standard).

One of the calculation results is the tightening torque / bolt force at assembly.

We use finite element analysis for special cases which cannot be visualised using analytical procedures.

Assembly

The results of design analysis have to be transformed into reality. This has to be done during assembly, i.e. by use of an appropriate assembly procedure by well-trained / experienced assembly staff. In daily life, this step is often underestimated.

To accomplish this task, amtec NA provides hands-on training, on one hand, and on the other: AMTEC uses controlled bolt tightening methods starting with torque-controlled bolt tightening up to hydraulic spanners and direct control of bolt forces, e.g. using ultrasonic equipment.

Systematic analysis of experience

Another reason why trained personnel is necessary:

Final knowledge of the real boundary conditions can only be collected on site, often during disassembly of the joints. Analysis of this information and feedback into the procedure leads to a correct design, to reliable, safe and tight flanged connections.

Experience is most effectively collected in a database. If, in addition to experience, the individual parts of the joints, assembly values or tools used are also recorded in the database, the operator has a comprehensive tool for Life Cycle Management.

Here you will find the direct route to some of our products and services:

- Test rigs: All-rounders and special equipment for gasket testing

- Test laboratories: Certificated gasket characteristics, special tests

- Calculation: Software and service provider for flange calculations

- Assembly: Hydraulic tightening tools and force control by measurement

- Databases: Essential Tool for Life Cycle Management